Day 8

Today has been an extension of yesterday's progress with setting up our ebb and flow. A new design was constructed by Fern and Sharron (see below). We finally got the flow timed just right!! Great job ladies! Towards the end of yesterday's workday we decided to add an overflow bulkhead to fish tank (1st level) to help drain water to reservoir and keep the pump constantly working. Now we could have just replaced our reservoir with a larger container but this didn't cross our mind. This morning we decided we would also purchase a larger reservoir to prevent tank from overflowing. The link below shows you how to build an ebb and flow.

http://www.ctahr.hawaii.edu/oc/freepubs/pdf/BIO-10.pdf

I spent the morning calibrating our spark probe which if you remember will give us baseline water condition data and which we will use to compare the accuracy of our sensor cluster. I then took readings for both tap water and our aquariums.

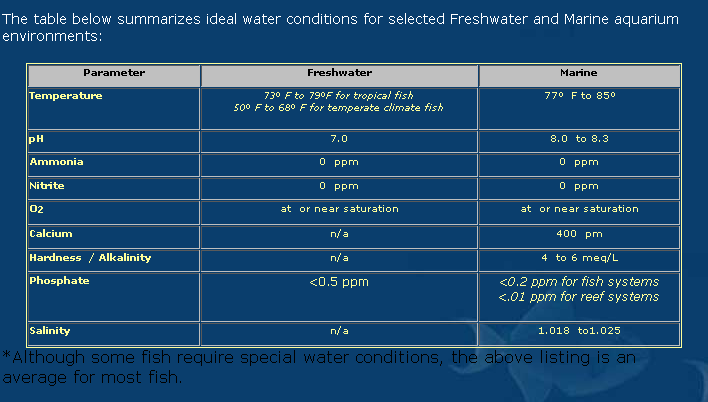

I've included a chart of an ideal tank water condition.

http://marinefish.net/html/ideal_water_conditions.html

All systems working beautifully!!

Sump

We have fish in there somewhere:)

Tomatoes

Ebb and flow (similar system as before but taller pvc for ebb)

atlas sensor

Digital reading

3 sensor probes integrated with arduino

pH buffers to calibrate sensors

Tap water testing

We spent the second part of the day in the library continuing with our research. We started our introduction, added 10 references, and began writing over creating a classroom table aquaponics.

Here are several sources that might help you as you are developing a remote sensor system to monitor an indoor aquatic system:

"Arduino - HomePage." Arduino - HomePage. N.p., n.d. Web. 17 July 2012. <http://www.arduino.cc/>.

Girod, Estrin, and Pottie Srivastava. "INSTRUMENTING THE WORLD WITH WIRELESS SENSOR NETWORKS." Proceedings of the IEEE (2001): 2033-036

Jun-Hong Cui, Jiejun Kong, M. Gerla, and Shengli Zhou. "The Challenges

of Building Scalable Mobile Underwater Wireless Sensor Networks for

Aquatic Applications." IEEE Network 20.3 (2006): 12-18

Mainwaring, Alan, Joseph Polastre, Robert Szewczyk, David Culler, and

John Anderson. "Wireless Sensor Networks for Habitat Monitoring." WSNA (2002)

Yang, Xiping, Keat G. Ong, William R. Dreschel, Kefeng Zeng, Casey S.

Mungle, and Craig A.

Grimes. "Design of a Wireless Sensor Network for

Long-term, In-Situ Monitoring of an Aqueous Environment." Sensors 2.11 (2002): 455-72

"YSI Incorporated | Water Sampling and Monitoring Equipment for Dissolved Oxygen, PH, Turbidity, Temperature, Level." YSI Incorporated | Water Sampling and Monitoring Equipment for Dissolved Oxygen, PH, Turbidity, Temperature, Level. N.p., n.d. Web. 19 July 2012. <http://www.ysi.com/>.

Andreas Graber, ranka Junge. “ Aquaponic Systems: Nutrient recycling from fish wastewater by vegetable production”